About Us

In the 90’s, finding a small company being certified to a quality management system was unthinkable and unheard of, as a matter of fact, most people in the Contracting Industry knew little or nothing of ISO 9001, Imagine convincing ourselves to even consider this expensive and humongous task, but we wanted a change, we wanted something to take us into a leadership position and give us that competitive edge. We wanted a system to reduce spoilage, we wanted to improve the image of the company, and to be able to market our business with confidence.

We started our ISO journey in 1997 to explore the opportunity of acquiring this certification and in 1999 we were one of the 1st company in our business to become certified to what was then known as ISO 9002:1994 (E) now (ISO 9001:2015), when we were audited by the AMERICAN PETROLEUM INSTITUTE, our third party auditors.

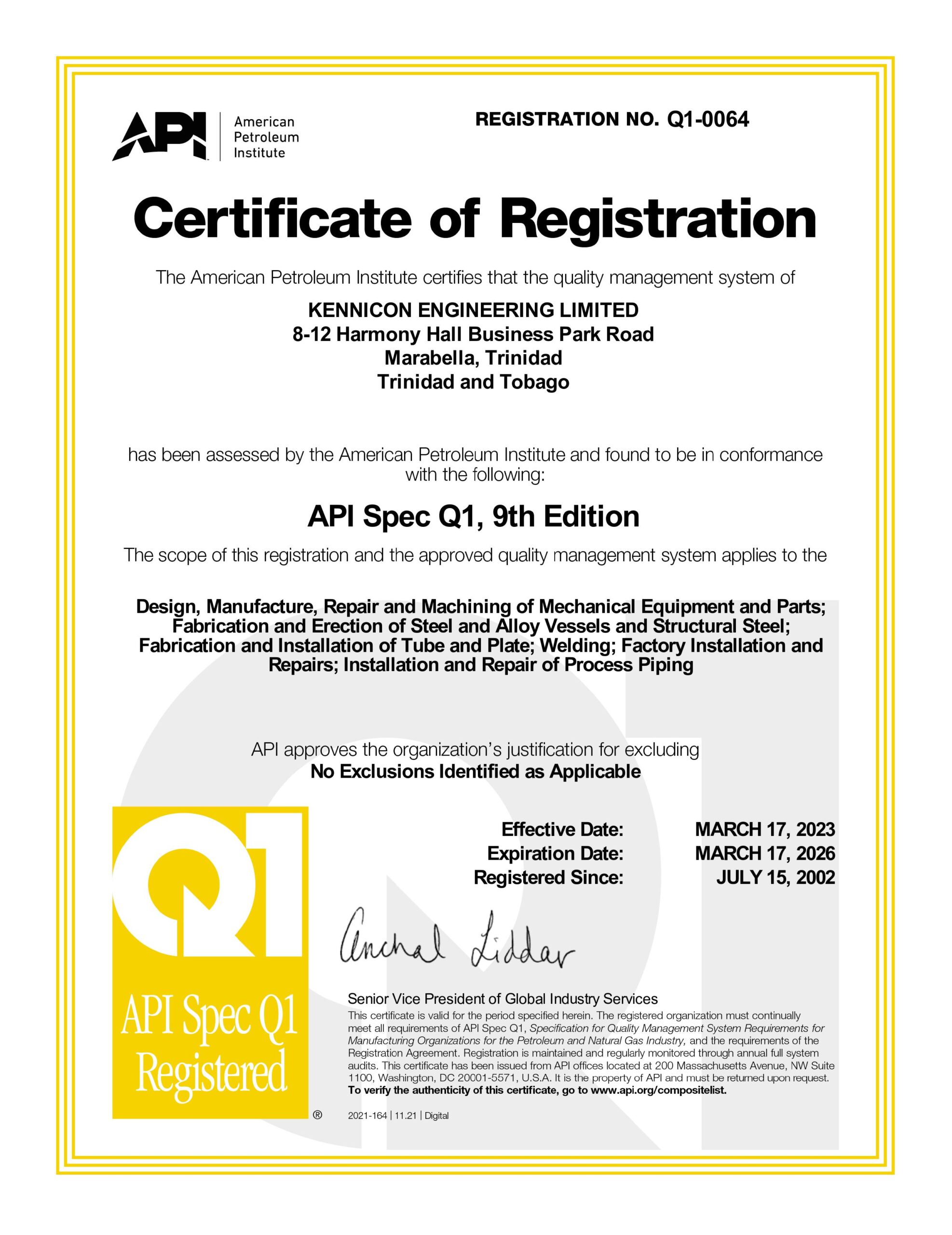

To strengthen our Quality Management System and add value to our credibility in the industry, we acquired additional certification relative to the oil and gas sector. As of July 15, 2002 we added the prestigious API Spec Q1. 9th edition to our certificates. ISO 9001 again upgraded its Standard and released their 2015 Version in September 2015 with a new Risk Base approach, and set a deadline of September 2018 for companies to comply. Kennicon was set in its agenda to be out front, and in September 2015 we became the 1st company in Trinidad to meet the requirements of the upgraded standard.

It is a fallacy to believe that you can market an ISO QMS System and we learned that at the early stages of our certification, what really occurred is our management style became very controlled, as there seems to be a Quality Procedure for everything. My choice is “product realization” as the key. Spoilage became very few and far. Delivery is always on time, this is what we market at Kennicon and our target remains at zero percent spoilage.

HEALTH, SAFETY AND ENVIRONMENT

Our journey towards yet another certification continues, this time on a local and regional setting. In 2010 we became involved in the pilot project established by the ENERGY CHAMBER OF TRINIDAD & TOBAGO (ECTT) towards the implementation of a Safe-to-Work (S.T.O.W) system. On January 04, 2011, Kennicon became the 4th company in Trinidad & Tobago to become S.T.O.W certified. Driven by continual improvement and management’s commitment to excel, another mildstone was achieved. On May 28, 2014, we became the first company to achieve 100% in all eleven elements of S.T.O.W, this unprecedented feat took us to a whole new level when we were featured in the ECTT magazine.

At Kennicon Engineering Limited, Health, Safety and the Environment is high up on our agenda as we strive to set new standards in the industry. Our highly spirited HSEQ team aspires to cross the hurdles of challenges with moral and ethical discipline, and plays an instrumental role of maintaining KEL’s HSE Management System.

Nazamudin Mohamed, Managing Director

OUR MISSION

To achieve complete customer satisfaction. In our efforts to meet customer requirements we shall incorporate applicable standards. Engauge in systems and procedures which will optimize our efficiency.

To be among the leaders in the field of engineering works and to set the standards for quality and safety in the construction sector. In doing so we shall continue to increase our market share.

To develop our human resources in order that they function with a high level of dexterity and display an attitude of professionalism. With progress, we shall enrich the life of every worker.

Quality Management System

Kennicon Engineering Limited is committed to providing quality products to our customers, as a result, Management decided to achieve this through the implementation of a Quality Management System. In August 1999 we were certified to ISO 9002 and as of March 2010 we have been upgraded to ISO 9001:2008. In March 2002 we were certified to API Specification Q1.

Our Quality Management System is well matured as we boast of many years of experience which makes the system run effectively and efficiently. Each process is well controlled to ensure the delivery of quality product to both internal and external customers.

We ensure that all employees are well trained to perform to their duties and equipment is satisfactorily maintained to enhance efficiency. All members of management and employees are committed to the continual improvement of our quality management system.

Health, Safety and Environment Statement

The management of Kennicon Engineering Limited is committed to ensure the safety of their employees, property, environment and all other stakeholders. The company ensures compliance with all applicable Health, Safety and Environmental (HSE) statuary and regulatory requirements such as the Occupational Safety and Health Act of 2000 and its 2006 agenda as well as the environmental management Act of 2000.

Our organization will be among the first of these companies t achieve compliance to the safe to work system (STOW-TT) presently piloted in conjunction with the Energy Chamber. Everyone at Kennicon Engineering Limited is responsible for the safety and health of themselves, others around them and the environment.

Management ensures that all employees are competent to perform their work in a safe manner and that machinery and equipment are maintained to ensure safe operations. We have developed and are developing policies and procedures to formalize and standardize the HSE aspect of our operations. Our aim is to eliminate occupational illnesses, injuries as well as harm to the environment.

Context of the Organization

Kennicon in meeting the requirements of our Quality Management System and by extension ISO 9001:2015 allows for the addressing of external issues. Interested parties are asked to post concerns and/or recommendation to our enquiries section so we can engage in meaningful dialog in addressing them with undue delay.

The following are some issues that we find to be relevant to our QMS:

| INTERESTED PARTIES | INTERNAL OR EXTERNAL | NEEDS & EXPECTATIONS | ISSUES |

| External Customers

|

External | 1. High quality of product/service

2. Reasonable price |

1. Ability to meet job specifications/requirements

2. Prompt courteous dealings at all times 3. Job delays/delivery time not met 4. Poor customer communications 5. Protect customer property at all times from damage or loss |

| External Providers of Product and Services (Suppliers, Sub-Contractors) | External | 1. Prompt payment (within 30 days)

2. Clear statement of requirements 3. Consistent lead times 4. Increase in business volume 5. Long term relationships |

1. Delays in receiving goods and services from suppliers

2. Poor quality of products and services provided 3. Not being aware and therefore not meeting KEL’s HSEQ requirements

|

| Regulatory Bodies | External | 1. Compliance with applicable laws and regulations

2. Timely and accurate submission of request for information/ reports. |

1. Not anticipating changes in regulatory requirements

2. Lack of knowledge of existing legal requirements

|

| Industrial Estate Management | External | 1. Advise on change of use

2. Adequate parking for customers and employees |

1. Proper liaison & communications with Estate Management in determining and meeting their requirements

2. Provision of adequate parking to prevent congestion etc. |

HSE & Quality Policy

QUALITY POLICY STATEMENT

The Kennicon Engineering Limited’s main objective is ‘Continuous Customer

Satisfaction’, which is achieved through providing and maintaining services and equipment at a satisfactory level of efficiency at all times and also through continuous development in the areas of training, processes and on time delivery. The quality management system developed involves the integrated efforts of all management functions and all our staff and commits the company to continual improvements of its operations.

The company identifies areas of training and retraining to meeting the ever changing customer requirements, increase the skills of employees and enhance competency.

Although meeting the customer’s and regulatory requirements is foremost, work is always conducted in a safe manner.

The Management of Kennicon Engineering Limited regularly establishes documents and communicates to supervisory staff, measurable quality objectives to ensure the continuing satisfaction of its customers and to continually improve the effectiveness of the quality management system.

The quality policy shall be reviewed for continuing suitability and communicated through leaflet distribution to all existing employees and new recruits, through meetings, placed on notice boards, through induction training, etc. and employees shall be made aware of what needs to be done to comply with the quality policy. It shall also be made available on KEL’s website/face book page for all interested parties (refer to the ‘context of the organization’).

HEALTH, SAFETY AND ENVIRONMENT POLICY STATEMENT

Identify Hazards and Control Risk

Activities will only be undertaken when risk assessments are conducted to identify hazards and actions are taken to minimize potential harm to people, environment and property.

Provide safe systems of work

Through the implementation of an in-depth and thorough Health, Safety and Environmental

Management System (HSE-MS), Management believes that a focused and active HSE program is crucial for the attainment in providing a safe workplace.

Kennicon Engineering Limited is committed realizing a zero-accident culture by continually improving on work practices with regards to safety and health of its employees and any stakeholders. Management is committed to ensuring that all activities will be conducted taking into consideration the impact on the environment.

Provide safe work conditions and equipment.

Management will provide adequate resources to ensure the implementation and management of the HSE-MS. This will include safe working conditions and equipment which are maintained to ensure consistent and safe performance, as well as devices which will prevent negative environmental impact.

Prevent accidents & incidents.

Management is committed to preventing accidents, incidents, injuries, ill health and hazardous conditions by investigating all accidents and near misses to identify root causes and implement corrective actions derived from these investigations. Lessons learnt can be used for continuous improvement.

Establish arrangements for reporting incidents and accidents

Management through its orientation and re-orientation process shall inform all employees to report all accidents, incidents and near-misses. Statistics provided shall be analyse and used to speak to employees in an effort to reduce the recurrence of these from happening. A safety conscious person shall be awarded for his/her effort.

Properly address emergency situations

An emergency situation is any situation that possesses an immediate threat to a person’s health, security, property, or environment. Management is committed to act expeditiously in treating with any such seen and/or unforeseen emergencies either by using internal and/or external resources.

Assure competence and provide training.

Management will ensure that all employees are competent to perform their duties effectively. Employees will be trained and evaluated to determine their competency and the effectiveness the training provided. Refresher training is also conducted periodically at prescribed intervals or as the need arises. Employees will be empowered to take action to ensure HSE policies and procedures are upheld.

Provide safe handling and transportation of harmful substances.

The Management of Kennicon Engineering Limited provides adequate training andequipment to ensure the safe handling and transport of harmful substances.

Consult with employees on HSE management and performance.

Audits will be conducted to review, ensure compliance and improve the performance of the

HSE-MS. Employees will be consulted on HSE issues and agreed resolutions will be effectively implemented to improve the performance of the HSE-MS.

HSE practices and procedures will be effectively communicated to all employees and stakeholders to ensure requirements are met.

Review the policy at regular intervals or when necessary

The company’s HSE policy will be reviewed and updated to keep abreast with the best practices of the industry. This shall be done at a minimum of every three (3) years.

Management commits itself to continual improvement of HSE performance by setting annual targets which will be reviewed semi-annually.

Commit the organization to comply with all relevant legislation at all times.

Kennicon Engineering Limited will comply with relevant statutory and regulatory requirements in respect to HSE by following requirements such as the Occupational, Safety and Health Act 2004 and the Environmental Management Act 2000 as well as meeting the requirements of the Safe-To-Work (STOW-TT) System 2009. For further details refer to procedure Legal Compliance LII-HSE-16.

Commit the organization to prevent harm to the environment.

The Management of Kennicon Engineering Limited is committed to minimizing the impact of our operations on the environment through:

- Eliminating or minimizing the discharges, emissions and waste.

- Utilizing materials, products and processes that conform to best environmental practice.

- Reducing the consumption of natural resources and using energy efficiently.

Corporate Social Responsibility

Kennicon Engineering Limited is committed to operating in an ethical manner that takes into consideration the social and environmental impact of everything it does. We are passionate about projects that protect and uplift society and the environment and those that preserve our heritage.

Have a look at some of our many completed and ongoing projects in our gallery. We encourage partnerships with businesses and individuals. If you would like to join us on any of our projects, please contact our marketing manager, Ms. Stacy Mohamed at 299-4938 Ext 2251.

Hurricane Maria Relief Effort

Date: September/October 2017

We partnered with the Ashnad Foundation to deliver in excess of 1000 tons of relief supplies to Dominica

Palmiste Windmill

Date: In Progress

Presently refurbishing the historic Palmiste Windmill.

Collection and Restoration of Local Antiques

Date: Ongoing

Provision of Flood Relief

Date: 20/10/2018

Kennicon Engineering Ltd out and about assisting flood victims with rescues and delivery of meals.

Key Personnel

Harripersad Seurattan

Purchasing Manager

Ameer Mohamed

HSEQ/H.R Manager

Terrence Mohamed

Senior Estimator Projects

Sharaz Shaun Mohamed

Company Director/B.D.O

Cliff Henry

Purchasing Manager

Stacy Mohamed

Marketing Manager / Creativity Division